- I am here:

- Products »

- Continuous loading elevators

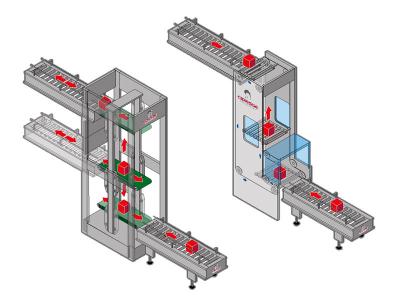

Continuous loading elevators

ETC bucket elevators-conveyors are designed and manufactured to optimise transportation of loose products of different consistencies (granular, powder, sticky products, etc), ensuring that they will arrive in perfect condition.

Equipped with one or more loading / discharge stations, they provide horizontal, vertical and diagonal transportation.

Because of their special modular configuration, these elevators-conveyors can even be used in confined spaces, guaranteeing the transportation of large volumes/ capacities in all situations.

HOW THE SYSTEM WORKS

The objects to be transported are positioned on the special platforms ensuring they are stable. They are conveyed by means of roller beds or loading belts, then chains transporters raise or lower the platforms to the loading/unloading height. Packs are continuously move in automatic mode.

UP & DOWN

Alternate loading system ensuring maximum loading/unloading flexibility. Ideal for light duty transportation of small loads.

Equipped with one or more loading / discharge stations, they provide horizontal, vertical and diagonal transportation.

Because of their special modular configuration, these elevators-conveyors can even be used in confined spaces, guaranteeing the transportation of large volumes/ capacities in all situations.

HOW THE SYSTEM WORKS

The objects to be transported are positioned on the special platforms ensuring they are stable. They are conveyed by means of roller beds or loading belts, then chains transporters raise or lower the platforms to the loading/unloading height. Packs are continuously move in automatic mode.

UP & DOWN

Alternate loading system ensuring maximum loading/unloading flexibility. Ideal for light duty transportation of small loads.

Technical features

» Load bearing structure made of painted carbon steel or stainless steel; galvanised sheet metal or stainless steel platforms (other materials are also avaiable depending on customer requirements)

» The platforms on which the objects to be raised/lowered are placed have been designed to guarantee that the packs remain stable during the raising/lowering stages and are avaiablein the standard version with "slats" and in the special version with "rods"

» Modular structure developed vertically

» Panels which can be removed to check the system is working properly when the machined is switched off

» Synchronisation of loading/unloading belt

» Synchronisation of loading/unloading belt

Advantages

» High loading/unloading frequencies

» Reduction in overall size as the machine has been developed vertically

» Low maintenance

» Easy to clean and disinfect

» Safety and reliability

Industries served

» Beverage

» Food

» Tinned and canned products in general

» Bags packaged products