- I am here:

- Products »

- Bucket elevators

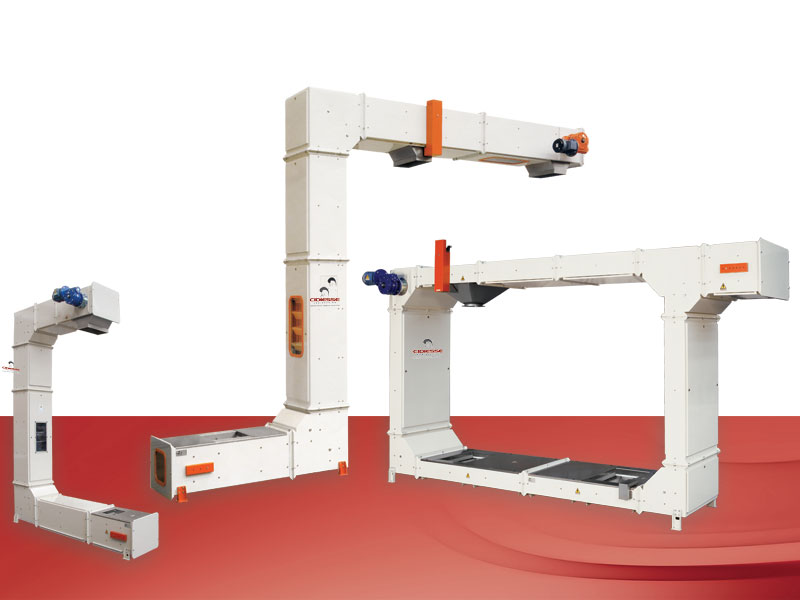

Bucket elevators

ETC bucket elevators-conveyors are designed and manufactured to optimise transportation of loose products of different consistencies (bulk products: granular, powder, sticky products, etc), ensuring that they will arrive in perfect condition.

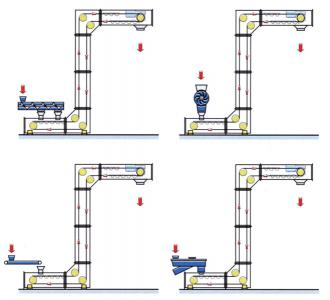

Equipped with one or more loading / discharge stations, they provide horizontal, vertical and diagonal transportation.

Equipped with one or more loading / discharge stations, they provide horizontal, vertical and diagonal transportation.

Because of their special modular configuration, these elevators-conveyors can even be used in confined spaces, guaranteeing the transportation of large volumes/capacities in all situations.

HOW THE SYSTEM WORKS

The buckets are filled with the product while they are moving and then emptied by means of electro-pneumatic or fixed systems.

The elevator is driven by a gear motor immersed in oil, with torque limiting device connecting directly by means of a joint to the drive shaft located in the orizontal top part.

Loading stations: depending on requirements, ETC bucklet elevators-conveyors are fitted with one or more loading stations. The product must be fed proportionately and evenly; (dosing units suitable for specific requirements can be supplied on request). Rubber strips or brushes prevent the product from spilling out of the loading stations.

Discharge stations: ETC bucket elevators-conveyors are normally supplied with a single discharge station ("fixed discharge"). On request by customers, several discharge stations can be installed with buckets which rotate 180° using special pivots and cams placed on the device ("electro-pneumatic intermediate discharge"). The openings throught which the product is discharged are usually fitted with a chute connecting them to silos, packaging machines or other systems.

HOW THE SYSTEM WORKS

The buckets are filled with the product while they are moving and then emptied by means of electro-pneumatic or fixed systems.

The elevator is driven by a gear motor immersed in oil, with torque limiting device connecting directly by means of a joint to the drive shaft located in the orizontal top part.

Loading stations: depending on requirements, ETC bucklet elevators-conveyors are fitted with one or more loading stations. The product must be fed proportionately and evenly; (dosing units suitable for specific requirements can be supplied on request). Rubber strips or brushes prevent the product from spilling out of the loading stations.

Discharge stations: ETC bucket elevators-conveyors are normally supplied with a single discharge station ("fixed discharge"). On request by customers, several discharge stations can be installed with buckets which rotate 180° using special pivots and cams placed on the device ("electro-pneumatic intermediate discharge"). The openings throught which the product is discharged are usually fitted with a chute connecting them to silos, packaging machines or other systems.

Structural features

» Load-bearings structure made of accurately press-forged, painted carbon steel and/or stainless steel sheeting

» The chains are made of galvanised carbon steel

» Modular structure

» Panel which can be removed/opened to check the system is working properly

» Panel which can be removed/opened to check the system is working properly

Optionals

» Galvanised, nickel-plated or stainless steel chains

» Equipped with manual or automatic bucket washing/drying systems

» AISI 304 or 316 stainless steel and/or teflon-coated buckets

» High-tech polimer buckets (ABS)

» Stainless steel wire mesh buckets

» Special loading systems

» Discharge came made of high-tech polymers (white or coloured) or aluminium are avaiable on ETC M series.

Advantages of our bucket elevators:

» High load capacity

» Safety and reliability

» Application flexibility

» Easy to install

» Easy to clean

» Low maintenance

» Reduced engaged spaces

Industries served

» Food

» Pharmaceutical

» Chemical

» Dairy-cheese

» Mineral -mining

» Ceramics

» Farming - livestock